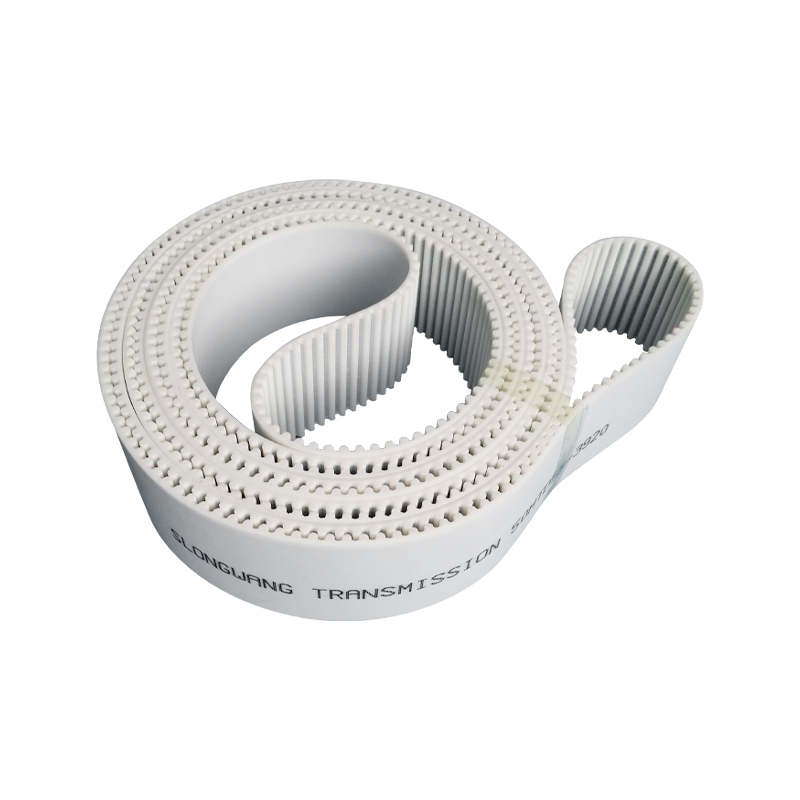

Classification of Timing Belts?

2025-01-25

Timing belts are quite familiar to many, but the specific classifications might be unclear to some. There are various types of timing belts, each suited for different machines. Broadly, they can be divided into the following categories: trapezoidal tooth timing belts, full arc tooth timing belts, half arc tooth timing belts, modified arc tooth timing belts, and precision arc tooth timing belts. Let's take a closer look at these types.

-

Trapezoidal Tooth Timing Belts:

- These are categorized into seven types: the lightest MXL, ultra-light XXL, ultra-light XL, light L, heavy H, extra-heavy XH, and extra-extra-heavy XXH. They are currently the most widely used timing belts in the market.

-

Full Arc Tooth Timing Belts:

- Models include HTD3M, HTD5M, HTD8M, HTD14M, and HTD20M. These belts offer high transmission accuracy and low noise.

-

Half Arc Tooth Timing Belts:

- Also known as high-torque timing belts, this term originates from Samsung in Japan. Models include S2M, S3M, S4.5M, S5M, S8M, and S14M. These belts are characterized by high torque and high precision, although they tend to be more expensive. The half arc timing belts also include the 8YU timing belt, suitable for high-speed transmission with a torque capacity of up to 1000 rpm/min, often used in medical equipment.

-

Precision Arc Tooth Timing Belts:

- Models such as 1.5GT, 2GT, 3GT, and 5GT are currently rare in domestic production and are primarily imported. They are generally used for high-precision transmissions and imported equipment. These models are produced by Gates, the world's first manufacturer of rubber V-belts, and are usually employed in automatic control equipment.

-

Modified Arc Tooth Timing Belts:

- Models like RPP5M and RPP8M feature a rabbit tooth design, offering good cornering effects, and are suitable for high-speed transmission. They are commonly used in robotic applications.

-

Special Tooth Timing Belts:

- These include the lightest T2.5, light T5, heaviest T10, and heaviest T20. Currently, the market offers five, ten, and twenty types. Many engineers may wonder about the difference between AT and T. The distinction lies in the bottom arc teeth for AT, while T features full trapezoidal teeth. Compared to AT, the T-type tends to offer more precision, reduced gaps, and lower noise levels.

Choosing the right timing belt based on the characteristics of your industry is crucial. The correct selection can enhance the efficiency of the timing belt and improve business profitability.

-

Tel: +86-400-670-3800

-

Tel: +86-574-58967770

-

Phone: +86-18867628822

-

FAX: +86-574-63990099

-

Email: llm@cn-slw.com

English

English 中文简体

中文简体