-

Ladder type straight tooth tooth size(unit:mm)

Type

Involute tooth profile

Tooth angle

Bottom width of cogging

ht(tooth height)

Fillet

Tip节距Pb 2y° bw hg 半径rb 半径rt MXL 2.032 (56)40 (0.61)0.67 0.69 0.30 0.23 XXL 3.175 50 0.41 0.84 0.35 0.30 XL 5.080 1.27 1.65 0.41 0.64 L 9.525 40 3.10 2.67 1.19 1.17 H 12.700 4.24 3.05 1.60 1.42 XH 22.225 7.59 7.14 1.98 2.39 XXH 31.750 11.61 10.31 3.41 3.18 T gear tooth size(unit:mm)

Type

pitch

Tooth angle

Top tooth width

ht(tooth height)

Fillet

TipPb 2y° brSE brN hg SE hg N 半径rb 半径rt T2.5 2.50 50 1.75 1.83 0.75 1.00 0.20 0.30 T5 5.00 2.41 3.32 1.25 1.95 0.40 0.60 T10 10.00 6.02 6.57 2.60 3.40 0.60 0.80 T20 20.00 11.65 12.60 5.20 6.00 0.80 1.20 AT type gear tooth size (unit:mm)

Type

pitch

Tooth angle

Bottom width of cogging

ht(tooth height)

Fillet

TipPb 2y。 S hg 半径rb 半径rt AT3 3.00 50 1.50 1.00 0.20 0.30 AT5 5.00 2.70 1.10 0.40 0.70 AT10 10.00 5.40 2.35 0.50 1.20 AT20 20.00 10.00 5.00 1.75 2.50 HTD circular arc tooth profile size (unit:mm)

Type

pitch

Groove width

Tooth height

Clearance circle

TipPb s hg 半径R 半径rt 3M 3.00 1.90 1.28 0.91 0.26-0.35 5M 5.00 3.25 2.16 1.56 0.48-0.52 8M 8.00 5.35 3.54 2.57 0.78-0.84 14M 14.00 9.80 6.20 4.65 1.36-1.50 20M 20.00 14.80 8.60 6.84 1.95-2.25 STPD/STS type gear tooth size (unit:mm)

Type

pitch

Groove width

Tooth height

Clearance circle

TipPb s hg 半径R 半径rt 3M 3.00 1.90 1.28 0.91 0.26-0.35 5M 5.00 3.25 2.16 1.56 0.48-0.52 8M 8.00 5.35 3.54 2.57 0.78-0.84 14M 14.00 9.80 6.20 4.65 1.36-1.50 20M 20.00 14.80 8.60 6.84 1.95-2.25

Picth tolerance

outside diameter pitch Distance between too coIse gears within 90 tolerance <25.40-0 0.03 0.05 >25.40-50.80 0.03 0.08 >50.80-101.60 0.03 0.10 >101.60-177.80 0.03 0.13 >177.80-304.80 0.03 0.15 >304.80-508.00 0.03 0.18 >508.00 0.03 0.20 Tolerance of outside diameter of pulley

outside diameter pitch Tolerance <25.40 +0.050 >25.40-50.80 +0.080 >50.80-101.60 +0.100 >101.60-177.80 +0.130 >177.80-304.80 +0.150 >304.80-508.00 +0.180 >508.00 +0.200 Allowable bounce of pulley end

outside diameter pitch Allowable bounce <101.60 0.10 >101.60-254.00 轮外径x0.001 >254.00 0.25+【(轮外径x254.00)x0.0005】 Allowable bounce of pulley warp direction

outside diameter pitch Tolerance <203.20 0.13 >203.20 0.13+【(轮外径x203.20)x0.0005】 -

Timing Pulley

Synchronous pulley is a mechanical transmission element, also known as synchronous pulley or synchronous belt pulley, mainly used to transfer torque and movement to maintain the synchronous performance of the transmission device. Synchronous pulley is usually made of metal or plastic.

Contact Us

Contact Us

Return To The Previous Page

Return To The Previous Page

ABOUT US

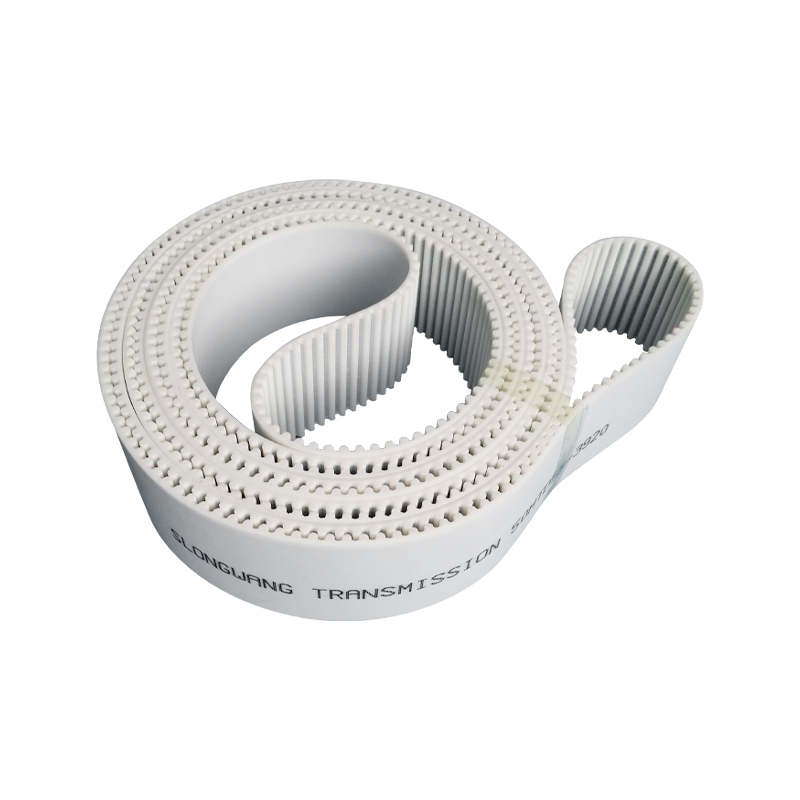

Ningbo Slongwang Synchronous Belt Co,.Ltd. specializes in the production of "Slongwang" brand synchronous belts and pulleys that meet international standard tooth profiles, as well as poly-V belts and pulleys, and other belt transmission products. Our product range includes rubber circular synchronous belts, rubber open-end synchronous belts, polyurethane PU circular synchronous belts, polyurethane PU open-end synchronous belts, polyurethane PU spliced synchronous belts, double-sided tooth synchronous belts, arc tooth synchronous belts, trapezoidal tooth synchronous belts, flat belts, V-belts, tooth bars, tooth plates, tensioners, and matching pulley wheels. With over 30 models and more than 3,000 specifications available, we are comprehensive manufacturers of synchronous belt products in China.

Located by the affluent and beautiful Hangzhou Bay, our company enjoys a scenic location with mountains and water, and a talented workforce. The old factory is situated along the 329 National Road in Longshan Town, while the new factory is conveniently located in the Longshan Industrial Park by the sea. In the past twenty years, through the hard work and innovation of our dedicated employees, we have established strong cooperative relationships with nearly a thousand clients in China and are expanding into international markets. Our company is equipped with advanced machinery, standardized manufacturing processes, comprehensive testing equipment, and strict enterprise management. Our technical management team, which includes some of the earliest developers of synchronous belt transmission products in China, boasts a wealth of professional experience. We have obtained ISO 9001:2000 certification, ensuring the quality of our products, which are widely used and recognized by clients in various industries both domestically and internationally, earning a good reputation for the "Slongwang" brand.

Our products are extensively used in various industries, including machine tools, textiles, printing, food packaging, home appliances, engraving, wire and cable, instruments, petrochemicals, tobacco, and communications, for the transmission of new mechanical drives.

Adhering to the traditional virtues of "sincerity, honesty, and earnestness," Slongwang advocates for high-quality and affordable products to achieve a win-win situation. We strive to lead the market with reliable products, more favorable prices, and faster delivery times, aiming to attract a broader range of partners. With a vision to establish a strong and large enterprise that stands the test of time, we are committed to creating a century-old business. We are eager to work with visionaries worldwide to forge a brilliant future.

Synchronous pulley consists of a circular belt with evenly spaced teeth on its inner circumference and a correspondingly engaging pulley. It combines the advantages of belt drives, chain drives, and gear drives. During transmission, power is transferred through the meshing of the belt teeth with the pulley's tooth grooves.

Synchronous pulley offers precise transmission ratios, no slippage, and constant speed ratios, ensuring smooth operation, vibration absorption, low noise, a wide range of transmission ratios (up to 1:10), and allowable linear speeds of up to 50 m/s. It can transmit power from a few watts to hundreds of kilowatts. With high transmission efficiency, generally reaching 98%, it is compact, suitable for multi-shaft transmission, and requires no lubrication, making it pollution-free and ideal for environments where contamination is not allowed or where working conditions are harsh.

Located by the affluent and beautiful Hangzhou Bay, our company enjoys a scenic location with mountains and water, and a talented workforce. The old factory is situated along the 329 National Road in Longshan Town, while the new factory is conveniently located in the Longshan Industrial Park by the sea. In the past twenty years, through the hard work and innovation of our dedicated employees, we have established strong cooperative relationships with nearly a thousand clients in China and are expanding into international markets. Our company is equipped with advanced machinery, standardized manufacturing processes, comprehensive testing equipment, and strict enterprise management. Our technical management team, which includes some of the earliest developers of synchronous belt transmission products in China, boasts a wealth of professional experience. We have obtained ISO 9001:2000 certification, ensuring the quality of our products, which are widely used and recognized by clients in various industries both domestically and internationally, earning a good reputation for the "Slongwang" brand.

Our products are extensively used in various industries, including machine tools, textiles, printing, food packaging, home appliances, engraving, wire and cable, instruments, petrochemicals, tobacco, and communications, for the transmission of new mechanical drives.

Adhering to the traditional virtues of "sincerity, honesty, and earnestness," Slongwang advocates for high-quality and affordable products to achieve a win-win situation. We strive to lead the market with reliable products, more favorable prices, and faster delivery times, aiming to attract a broader range of partners. With a vision to establish a strong and large enterprise that stands the test of time, we are committed to creating a century-old business. We are eager to work with visionaries worldwide to forge a brilliant future.

Synchronous pulley consists of a circular belt with evenly spaced teeth on its inner circumference and a correspondingly engaging pulley. It combines the advantages of belt drives, chain drives, and gear drives. During transmission, power is transferred through the meshing of the belt teeth with the pulley's tooth grooves.

Synchronous pulley offers precise transmission ratios, no slippage, and constant speed ratios, ensuring smooth operation, vibration absorption, low noise, a wide range of transmission ratios (up to 1:10), and allowable linear speeds of up to 50 m/s. It can transmit power from a few watts to hundreds of kilowatts. With high transmission efficiency, generally reaching 98%, it is compact, suitable for multi-shaft transmission, and requires no lubrication, making it pollution-free and ideal for environments where contamination is not allowed or where working conditions are harsh.

News

-

Jan 25,2025Expanding the market space for synchronous belts can create significant economic value, which greatly aids development. ...Read More

-

Jan 25,2025Timing belts are quite familiar to many, but the specific classifications might be unclear to some. There are vario...Read More

-

Jan 25,2025Timing pulleys commonly face two significant issues: tooth surface wear and tooth breakage. Below, we analyze the causes...Read More

-

Jan 25,2025When it comes to selecting synchronous pulleys, we typically refer to the pulley selection manual. If the synchronous be...Read More

get in Touch

English

English 中文简体

中文简体